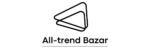

Manufacturing technology plays a pivotal role in today’s industrial world. But what is Fabrication technology? Simply put, it is the use of machines, tools, processes, and knowledge to produce goods efficiently and effectively.

Modern Fabrication technology combines automation, robotics, digital systems, and advanced materials to improve production speed, reduce costs, and enhance quality. With industries evolving rapidly, understanding this concept is essential for businesses and professionals alike.

Industrial engineering not only focuses on production but also emphasizes innovation. It integrates computer-aided design (CAD), computer-aided manufacturing (CAM), and smart systems to create highly optimized production workflows. This technology has become the backbone of sectors such as automotive, electronics, aerospace, and consumer goods. Companies using modern Fabrication technology gain a competitive edge through increased efficiency, reduced errors, and sustainable practices.

The Evolution of Fabrication Technology

Manufacturing technology has evolved remarkably over time. From simple hand tools to sophisticated robotics, each phase of industrial development has transformed how goods are produced. Early manufacturing relied heavily on human labor, but the Industrial Revolution introduced machines that increased efficiency and reduced manual work.

With the rise of electronics and computing, digital technology transformed Industrial technology further. Automation, programmable machines, and computer systems allowed precision, consistency, and speed never seen before. Today, advanced manufacturing includes AI-driven robotics, 3D printing, and IoT-enabled machines, making production smarter and more adaptable.

Integration of robotics and automation, the use of digital twins and simulation for design, adoption of advanced materials for lightweight and durable products, and an emphasis on sustainable and eco-friendly production are all key aspects of modern manufacturing technology. Together, they enhance efficiency, reduce errors, and promote environmentally responsible production.

Key Components of Industrial Technology

Modern Industrial engineering is built on several core components that work together to improve productivity and quality. Understanding these elements helps businesses optimize their operations.

Automation Systems

Automation systems reduce the need for human intervention in repetitive or routine tasks. By using programmable machines and control systems, industries can improve production speed, minimize errors, and maintain consistent quality. Automation also frees up human workers for more strategic and creative roles, boosting overall efficiency.

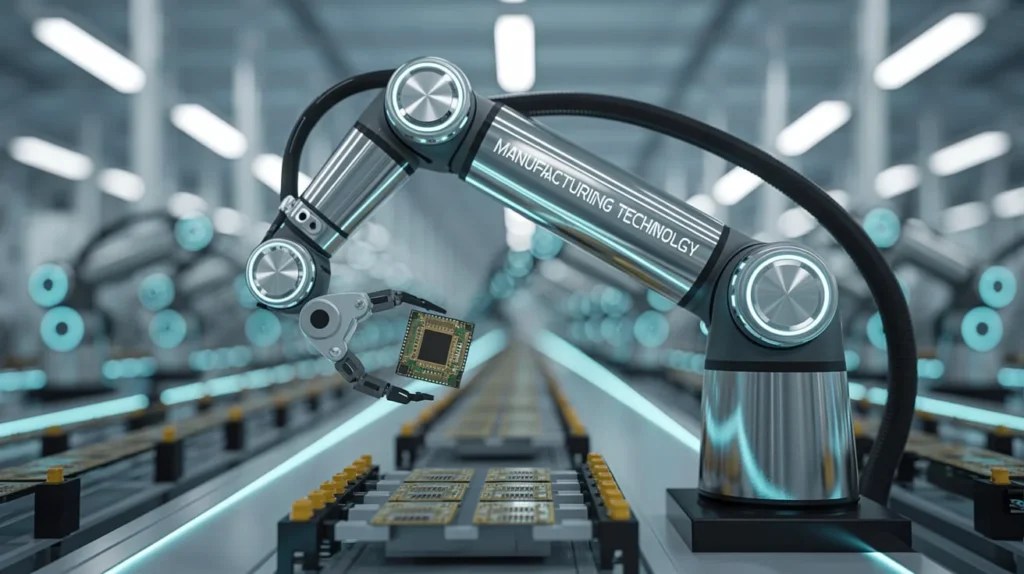

Robotics

Robots are designed to handle complex, precise, or hazardous tasks that may be challenging or unsafe for humans. They ensure consistent quality and high-speed production while reducing workplace accidents. Robotics is widely used in assembly lines, material handling, and inspection processes across industries.

Computer-Aided Design (CAD) and Manufacturing (CAM)

CAD and CAM tools allow engineers to create and simulate product designs digitally before actual manufacturing. This process reduces errors, saves time, and optimizes material usage. By integrating CAD/CAM, companies can accelerate prototyping, improve design accuracy, and streamline production workflows.

Industrial Internet of Things (IIoT)

The Industrial Internet of Things connects machines, sensors, and devices to monitor equipment in real time. IIoT helps predict maintenance needs, prevent downtime, and optimize production processes. By analyzing collected data, companies can improve efficiency, reduce costs, and make informed operational decisions.

Benefits of Industrial Technology

The adoption of advanced Industrial technology offers numerous advantages that transform industrial operations. Companies can achieve higher production speed and output while minimizing human errors and reducing operational costs. Enhanced product quality and precision ensure customer satisfaction, and improved workplace safety protects employees from hazardous tasks. Additionally, Industrial technology provides greater flexibility for product customization, allowing businesses to respond quickly to market demands.

Advantages:

- Increased production speed and output

- Reduced operational costs and human errors

- Enhanced product quality and precision

- Improved workplace safety

- Greater flexibility for product customization

Applications Across Industries

Manufacturing processes find wide applications across various industries, driving efficiency, innovation, and precision. In the automotive sector, robotics and CAD streamline production and design. The electronics industries benefit from precise equipment for components, while aerospace relies on advanced materials and simulation for safety and performance. Consumer goods manufacturers use smart machinery to ensure quality control and efficient packaging, improving overall productivity.

Automotive

In the automotive industry, Mechanical technology plays a crucial role in enhancing production efficiency and precision. Robotics is extensively used on assembly lines to perform repetitive or heavy tasks, reducing human error and increasing speed. Additionally, CAD (Computer-Aided Design) enables engineers to design and simulate vehicle components digitally, ensuring accuracy and optimizing performance before actual production.

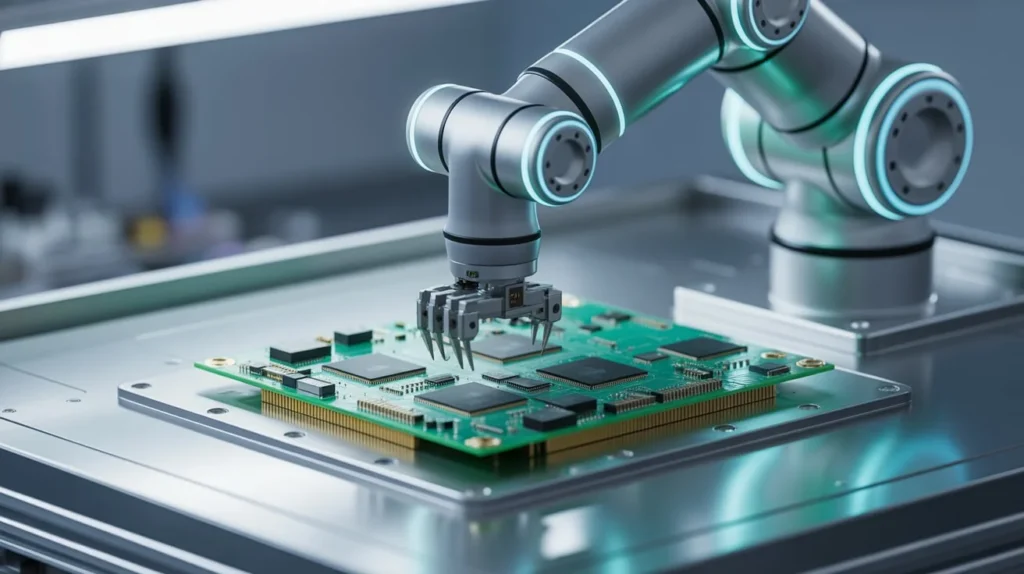

Electronics

Manufacturing processes in the electronics sector focus on precision and reliability. Advanced machinery and automated equipment handle delicate tasks such as assembling circuit boards and components, which require high accuracy. These technologies reduce defects, improve quality control, and enable the mass production of electronic devices efficiently.

Aerospace

In aerospace, Fabrication technology ensures safety, performance, and innovation. Advanced materials like lightweight alloys and composites are used to build aircraft components, while simulation tools allow engineers to test designs digitally under various conditions. Robotics and automated systems further enhance precision and reduce the risk of human error in production processes.

Consumer Goods

For consumer goods, Industrial engineering enhances speed, consistency, and product quality. Smart machinery automates packaging, labeling, and quality control, ensuring each product meets standards. This allows manufacturers to scale production, reduce operational costs, and respond quickly to changing market demands.

Future of Fabrication Technology

The future of Industrial engineering is driven by smart factories, AI, and sustainable practices. Companies are increasingly adopting artificial intelligence, machine learning, and predictive maintenance to streamline operations. Additive manufacturing, like 3D printing, will continue to transform prototyping and production, making small-scale manufacturing cost-effective.

As industries focus more on sustainability, green manufacturing technologies will reduce waste, conserve energy, and improve environmental impact. The combination of digital innovation and ecological responsibility is set to define the next era of production.

Challenges in Implementing Fabrication Technology

Despite its advantages, integrating industrial technology comes with challenges. Companies must address these to fully benefit from modernization.

Transitioning from traditional systems to automated or digital ones requires significant investment. Employees need training to manage and maintain advanced machinery. Additionally, data security and system integration are critical to ensure seamless operations.

Challenges:

- High initial cost of equipment and software

- Skill gap in the workforce

- Complex integration with existing processes

- Maintenance and cybersecurity issues

Conclusion

Understanding what manufacturing technology is crucial for anyone involved in modern production. It encompasses tools, machines, processes, and digital systems that improve efficiency, quality, and sustainability. From historical machinery to AI-driven smart factories, Fabrication technology has transformed industries globally.

Businesses that embrace advanced industrial technology gain competitive advantages through faster production, precision, and innovation. As technology continues to evolve, staying updated is key to remaining relevant and efficient in today’s industrial landscape.

Fabrication technology is not just about producing goods; it is about shaping the future of industries, enhancing sustainability, and creating smarter production systems that meet global demands efficiently.